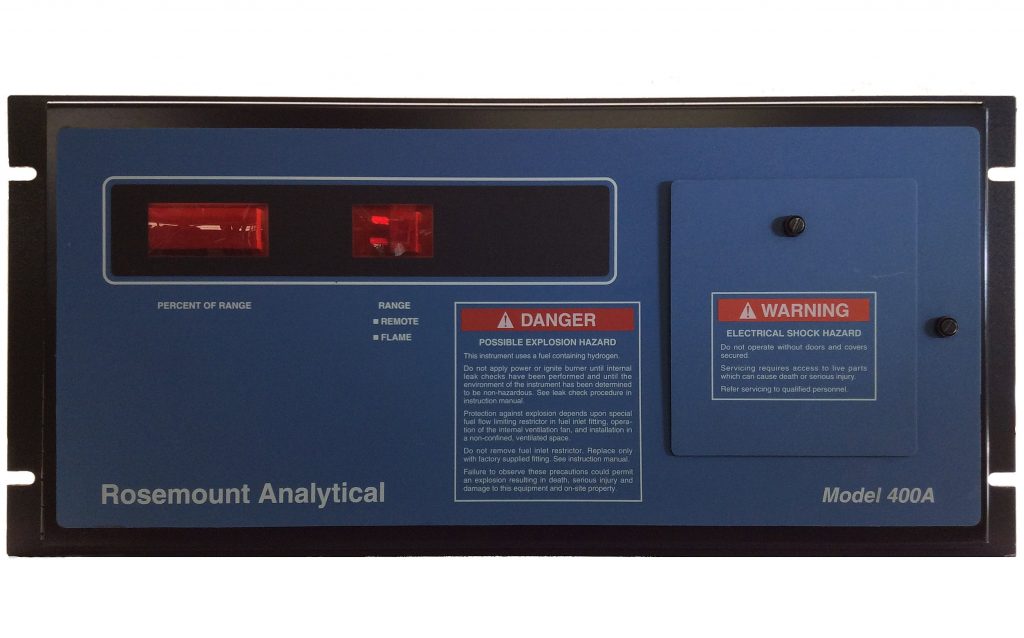

As of September 30, 2023, the Rosemount 400A has been officially obsoleted by OEM (Emerson – Rosemount Analytical) with NO OEM PARTS or FACTORY SUPPORT. There is good news though; RIGAS plans to support this analyzer for at least the next ten (10) years, and maybe longer. If you are an end-user, you can help us help you by NOT throwing away good components (boards, regulators, etc.). Everything is repairable. Here are a few examples:

1. Main Electronics Board (pre-2009 vintage) – rarely fails. Shipping sometimes causes the big transformer to be ripped off the board

• Fixable. We have new transformers.

2. 4-20 mADC card gets noisy or fails outright

• Usually a few capacitors dry out causing the “charge pump” to misbehave. We replace the capacitors and fully test the board (includes linearity checks).

3. Backpressure regulator – the rubber diaphragm dries out, becomes brittle, and then it doesn’t regulate pressure very well.

• We install a new diaphragm and relap the valve seat; the result is near PERFECT operation (very little seat leakage and great pressure control).

4. Ribbon cables – they get pinched or scraped.

• We build our own cables.

5. Sample capillary – it gets clogged over time causing a lack of sensitivity.

• It can be cleaned but we’d rather just replace the old capillary (and possibly reuse your old fitting); capillaries are just soldered into a Parker-Hannifin, tube-end reducer, stainless steel fitting using a Silver bearing solder.

• Additionally, if your application is unique, we can build a unique capillary.

6. Thermal insulation – it becomes unglued.

• We replace the insulation where needed and/or reglue the old insulation.

7. Burner jet gets fouled causing false flame problems or noisy readings.

• We make our own jets.

8. Burner contact gets old and brittle, and eventually breaks causing a total loss of analyzer functionality.

• We make our own burner contacts (a.k.a., Hot Dogs).

So, in other words, just about everything is repairable. So, let’s partner up and keep your analyzer running!!!

A side note: Emerson-Rosemount does NOT have a replacement analyzer for the 400, 400A series. RIGAS is toying with the idea of building a replacement analyzer and calling it the RIGAS 400R. It will be VERY similar to the Rosemount 400A but maybe a little easier to operate. We plan to change the display to read “ppm” rather than percent (%) of scale. It will also have built in diagnostics for those key parameters that we always ask you about when you call in for technical support. In the meantime, RIGAS does recommend the Teledyne 4020 THC analyzer (or one of the sister units, like the 4040).