If asked how we would supply a sample source to a ‘pressure sensitive’ analyzer, we would tell you to control the source pressure and not throttle the source pressure/flow.

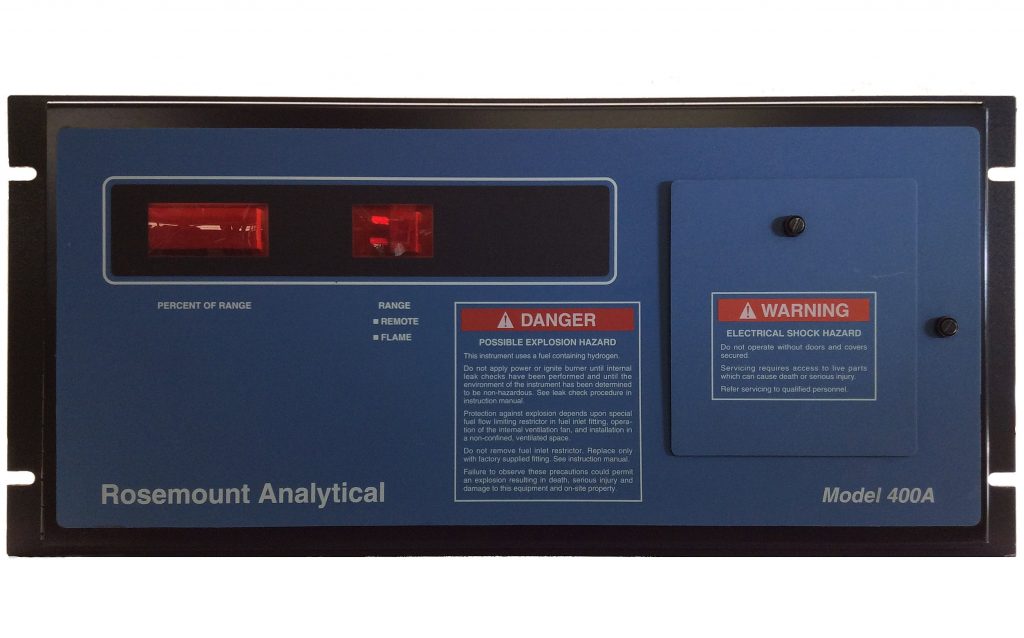

We’re in the “control the source pressure” camp and not of the “throttle the source flow” camp. The Rosemount 400, 400A, 951A, 951C, 951E, NGA-FID1, NGA-HFID, and NGA-CLD series analyzers are sample pressure dependent analyzers, that is, this type of analyzer utilizes sample source pressure to create the motive force for sample to flow through a restrictor or capillary (and, in rare instances, through a mass flow controller). In order for this type of analyzer to determine the % (percent) or PPM (parts per million) concentration of its sample, it requires a stable pressure at key pneumatic junctions within the analyzer itself. Typically, this junction is near the sensing element and is usually flow controlled by a capillary tube or precision restrictor. To ensure that this pneumatic junction is controlled at some value, 3 psig for instance, a back pressure regulator (BPR) is employed.

This is how it is supposed to function: when sample is applied, the pressure within the analyzer builds up until it reaches the control point (a.k.a., set point) of the BPR; if the pressure continues to build, the BPR bleeds the excess pressure off to a vent header or waste dump. The bleed off is sometimes referred to as bypass flow. This action by the BPR controls the pneumatic junction at a predefined value … as long as there is excess source pressure.

If we control the source pressure (i.e., sample pressure) then we can control the bypass rate as well, simply by changing the source pressure, that is, you control the delta-P (delta-pressure) between the two systems … and you get the benefit of great analyzer accuracy simply due to more accurate control of the key pneumatic junction.

Here are examples (assume that your analyzer runs at 3 psig internal sample pressure):

Example 1:

1. Source pressure = 3psig

2. Analyzer is happy (that is, the capillary is maintained perfectly at 3psig by either the internal backpressure regulator [BPR] or the external forward pressure regulator so the THC calibration is valid)

3. But there is no bypass flow so response time to process excursions is VERY poor.

Example 2:

1. Source pressure = 5 psig

2. Analyzer is happy (that is, the capillary is maintained perfectly at 3 psig by the internal backpressure regulator [BPR] so the THC or NOx calibration is valid)

3. and because there is a pressure delta between source pressure and control pressure, there is significant bypass flow (within the capabilities of the BPR) so response time to process excursions is good

4. let’s assume that this creates 1200 cc/min of sample bypass flow (this assumption used in the next example)

Example 3:

1. Source pressure = 4 psig

2. Analyzer is happy (that is, the capillary is maintained perfectly at 3 psig by the internal backpressure regulator [BPR] so the THC calibration is valid)

3. because there is a pressure delta between source pressure and control pressure, there is significant bypass flow (within the capabilities of the BPR) so response time is OK

4. we probably lost half of our bypass from the previous example so let’s assume that this creates 600 cc/min of sample bypass

5. We’re still OK. No loss of accuracy. Response time to process excursions might be an issue on some systems.

Example 4:

1. Source pressure = 25 psig

2. Analyzer is NOT happy. The internal backpressure regulator [BPR] is bypassing at its maximum rate (with a nasty “singing” sound) and has lost control of the 3 psig at the sample capillary so the THC or NOx calibration is NOT valid).

3. But there is significant bypass flow so response time is good … it’s just not giving us valid readings!

4. All process readings will read much higher than normal, and thus, inaccurate.

This might be a good time to talk about regulators and back pressure regulators. It should be noted that as source pressure climbs from setpoint to the end of the control band of the regulator, there will be a slight upward creep of the control pressure value; this in turn affects the key pneumatic junction and the analyzer’s calibration curve. This has to do with the internal operation of the regulator. In order to correct for something like this, you might have to invest in a digital controller and I/P module to control the dome loading of a specially designed regulator (one that controls pressure mechanically but will also accept an external pneumatic signal to bias its setpoint one way or another).

Some companies throttle the inlet and ‘hope’ that the capillary is maintained at the correct pressure. You ‘could’ assume you have positive control of the capillary pressure by virtue of the fact that there is bypass flow. But we’ve seen significant interaction between a throttled source and the internal control pressure (BPR); so much interaction that we don’t endorse this method of control. It’s a method of control that will not yield the most stable calibrations or process readings. So if you’re looking to get superior accuracy, control the source pressure and let the delta pressure (D/P) control the bypass rate.

Attempting to control the bypass rate at the back of the analyzer at the analyzer’s bypass exhaust port is very bad. This will essentially take the internal BPR’s control out of the equation … you won’t have any positive control of the pressure at the capillary head … so your calibrations will be at the whim of the source pressure (or source flow … which in turn creates a pressure).

We’ve always wanted to make YouTube video of this and put it out there to dispel all of the misinformation. Watch for its release which will star Rachel Ward (Dead Men Don’t Wear Plaid) as Juliet.

Call us at 877-616-0600 if you want the verbal version! (Just in case the written version doesn’t make any sense!)