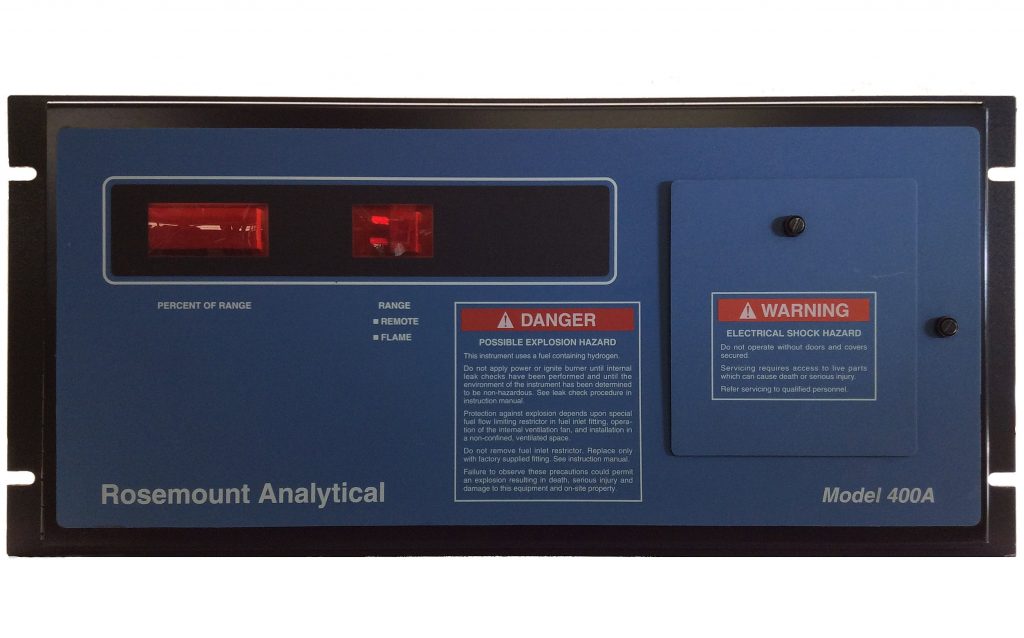

This particular analyzer is one of RIGAS’ favorites to work on (i.e., repair).

Here is a list of some of our checks that we perform before we release your analyzer for shipment:

1. Noise on range X1 should be minimal (±1 count)

2. All ranges should be correlated (especially those with an optional range trim board)

3. Response to certified calibration gas should be equal to or better than factory specifications

4. When TP5 = 5 VDC then [a] the display reads 100.00, [2] analog output is either 100mV or 1V or 5V (depending on jumper configuration, [3] isolated current output = 20 mADC

5. Analyzer is clean

6. Insulation is re-glued

7. Frayed wires are fixed

8. Plexiglas is grounded

9. A/C power switch leads are coated with “liquid electrical tape” to prevent inadvertant electrical shock to the end user

10. Ribbon cables are pristine

11. Rear terminal strip has a sticker that shows what functions are on what terminals

12. Zero pot (potentiometer) is greater than 50% (the higher the number here, the less contamination in the analyzer tubing)

13. It needs to look good again (paint job if necessary)

14. Flame safety circuits MUST work properly

15. Backpressure regulator works as designed (and controls at a very reliable value)

16. There’s a bunch more, but we don’t want to bore you with the entire list!

Give us a try by calling us at 877-616-0600.